With the improvement of people’s living standards, automobiles have become a necessity for people to travel, and the demand for automobiles is also increasing. The production requirements and production technology of automobiles are also continuously improved. For example, the production of auto parts requires strict inspections, including Various arcs and curved surfaces of accessories such as doors and bumpers.

Customer needs:

1. Detection object: car door

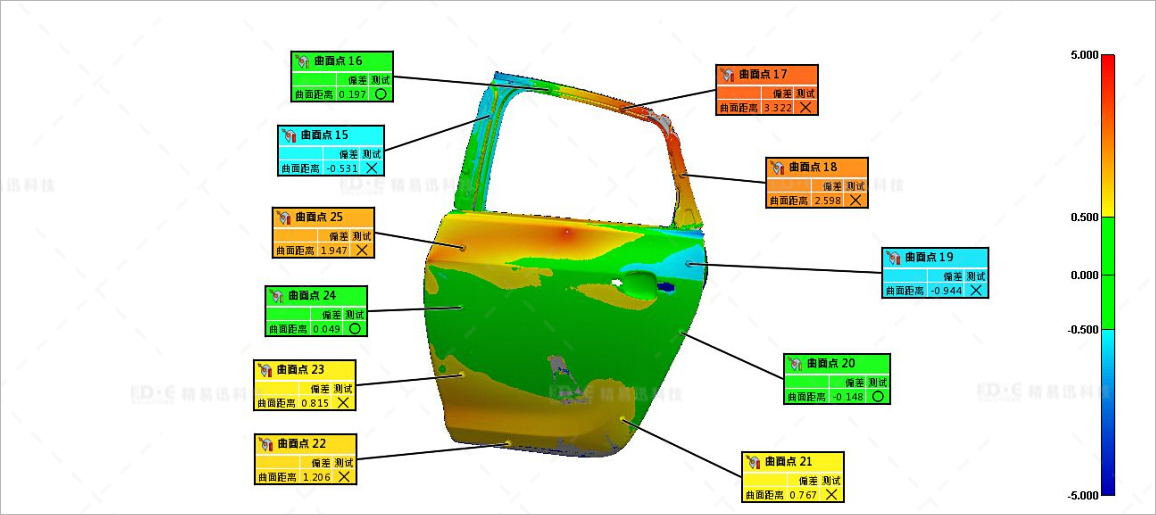

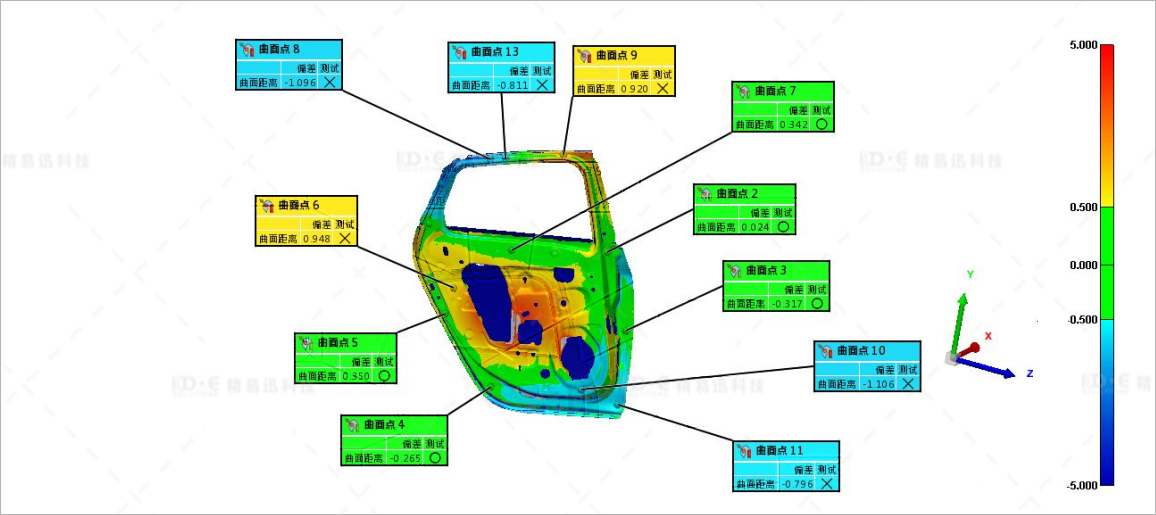

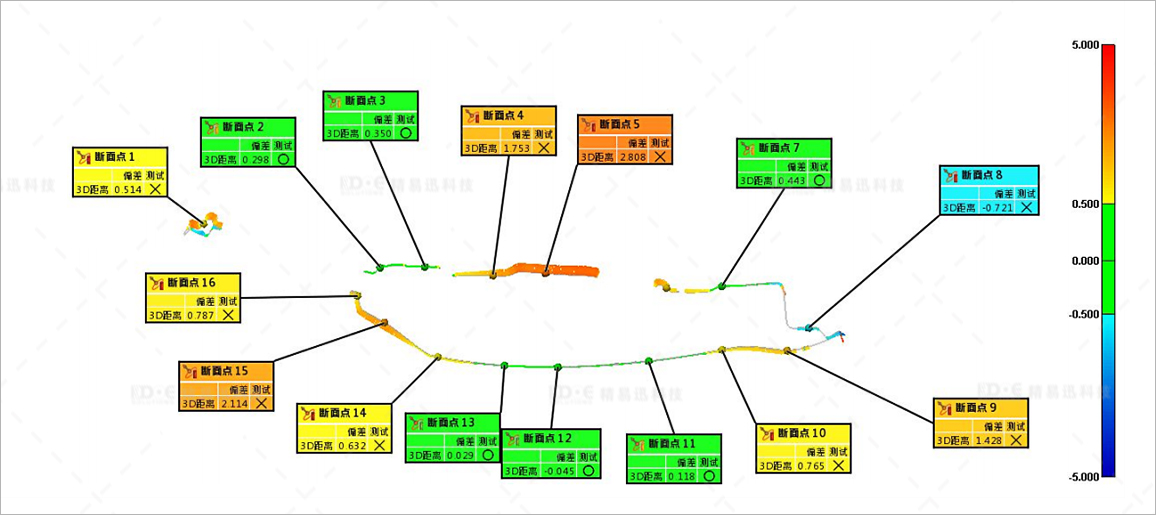

2. Customer needs: Quickly obtain the three-dimensional model of the car door for quality inspection (door 3D surface inspection), and find that the quality of auto parts requires 3D inspection of the production mold, and analyze and judge the problem through 3D surface inspection.

3. Current difficulties that customers need to solve

Automobile doors have high requirements for surface detection, traditional three-coordinates are difficult to detect, the detection efficiency is slow, and it is difficult to obtain complete data of complex parts. Automobile doors are easily deformed and difficult to detect. The traditional manual measurement accuracy is not high and cannot detect the specific errors of product processing, especially the detection of the curvature and angle of the curved surface of automobile parts.

Car door 3D full-size inspection solution (handheld blue light 3D scanner)

1. Preparation

Choose a suitable 3D scanner, the technical engineer chose a handheld blue light 3D scanner (eSharp P13) to scan the car door accessories, and the marking is completed in 1 minute. The larger marking points on the car door can be directly pasted on the car door (as shown below)

2. To scan the workpiece, our technical engineer uses a handheld Blue ray 3D scanner (eSharp P13) to scan and obtain the 3D data of the car door, which takes 5 minutes.

3. The car door is compared with the model for 3D detection. The parameters such as the contour of the car door and the curvature of the curved surface are detected, and the deviation results are marked.

The value of car door 3D inspection solutions

1. Quality inspection

The 3D shape data of the scanned object can be obtained through the handheld blue light 3D scanning technology. The 3D comparison and analysis of the obtained 3D scanning data and the original 3D digital model can easily obtain the deviation value of each position, which is the size of large curved surfaces and complex structures. Testing provides a good solution. In addition, data such as coaxiality, hole pitch, assembly clearance, etc. can be easily obtained by fitting three-dimensional data.

2. Analysis of exercise status

The handheld blue light 3D scanner performs 3D scanning on the opening and closing parts of car doors, trunks, etc. in different states, and can obtain the structural relationship of the opening and closing parts in different motion states, providing precision for subsequent structural analysis, size design and other links Three-dimensional data.

The highlights of the handheld blue light 3D scanner used in the car door 3D inspection solution

1. No environmental restrictions, non-contact scanning

2. It is not limited by the size of the workpiece under test

3. Full-size inspection of workpiece (batch inspection can be done)

4. Easy to operate and learn

5. Multi-product testing and diversification (such as product testing, mold testing, etc.)

6. Reverse design and development can be realized

Summary of 3D inspection solutions for car doors:

Jingyi Xun uses a handheld Blue light 3D scanner to conduct 3D scanning of car doors, quickly obtain complete 3D data of car doors, and conduct 3D dimension detection and 3D surface detection of car doors at different stages in the production process. Can generate accurate CAV surface detection report, analysis point, line, plane omni-directional deviation. Handheld Blue light 3D instrument improves the efficiency of quality inspection department, greatly reduces the cost of inspection, and expands the competitive advantage of manufacturing enterprises.

Related Products

eSharp P13 Handheld 3D Scanner (Blu-ray)

0755-86131192

0755-86131192

0755-86131192

0755-86131192