In the trend of economic development and urbanization, cars are the first choice for daily travel, and traffic jams and accidents are very common. For the safety of the car are very concerned, the requirements of car brake parts are constantly improved, such as the modification of car brake parts need to do strict requirements, including the various sizes of the parts, radian, curved surface and so on. The traditional 3D detection methods for auto parts, such as three coordinates, three dimensions, 2.5 dimensions, etc. are adopted. The detection accuracy for brake parts is high, and the efficiency will be relatively slow if the curved surface radian needs to be detected.

client needs:

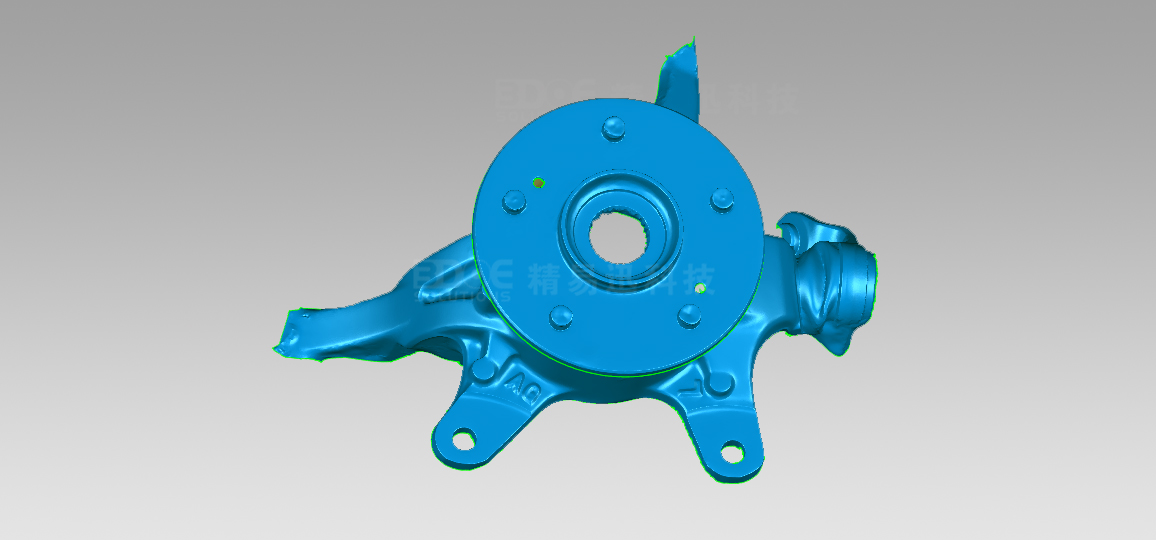

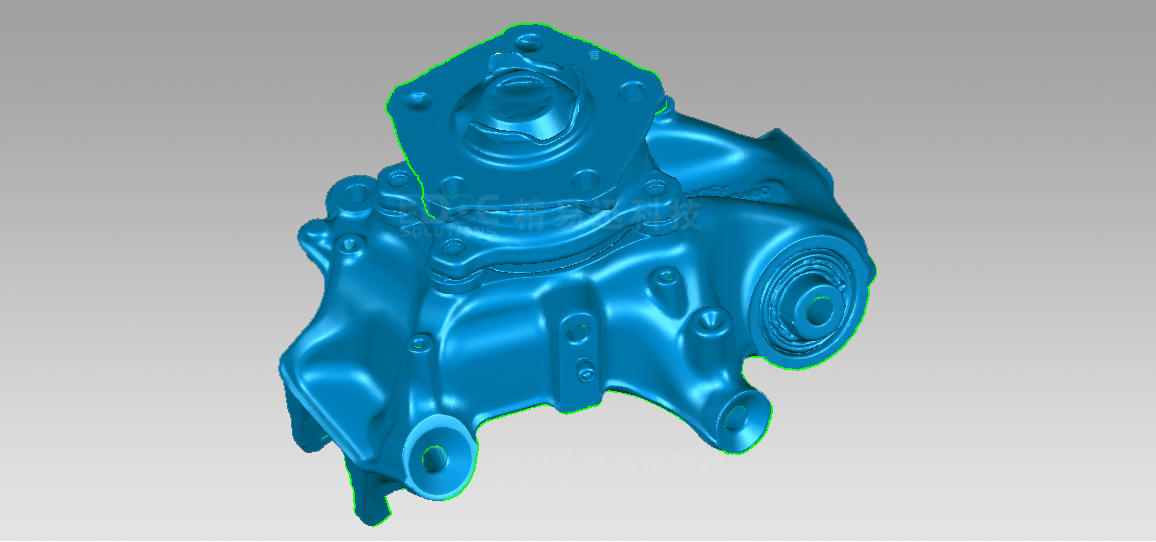

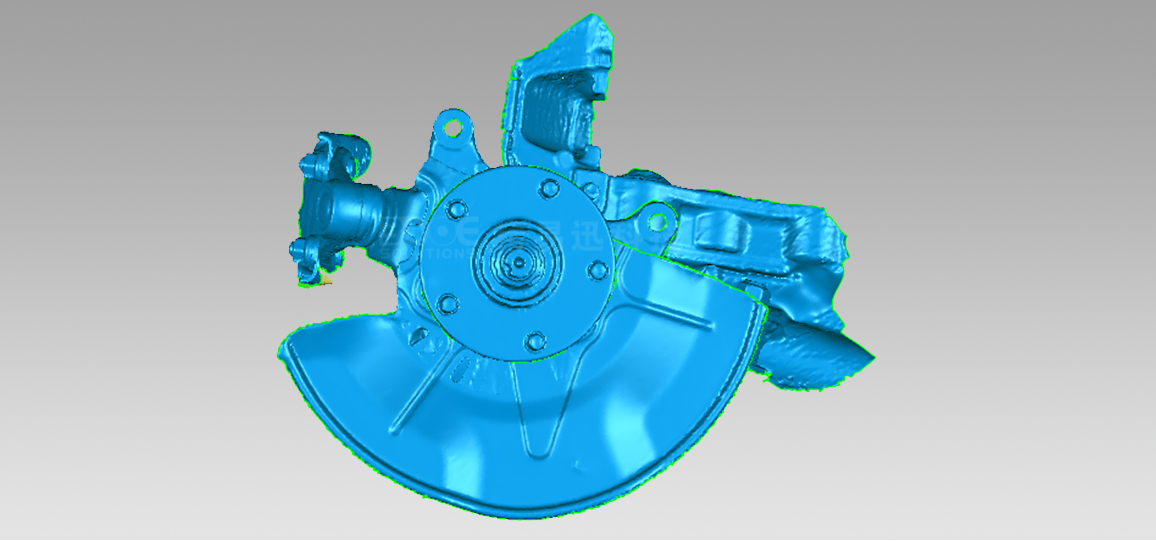

1. Detection object: auto parts (brake assembly claw)

2. Customer needs: Quickly obtain the three-dimensional model of auto parts for simulation assembly, and find that the dryness of auto parts requires 3D inspection of the production mold, and analyze and judge the problem through 3D full-size inspection.

3. Current difficulties that customers need to solve:

1) The surface accuracy of automobile parts is required to be high, the traditional three-coordinates are difficult to measure, the measurement efficiency is slow, and the complete data of complex parts is difficult to obtain.

2) It is difficult to measure the abnormal shape of auto parts, and the traditional manual measurement is not accurate enough to detect the specific error of the product, especially the detection of the curvature and angle of the curved surface of the auto parts.

3D detection solution for auto brake parts (Photo-type 3D scanner)

1. Preparation: Choose a suitable 3D scanner. The technical engineer chooses a camera-based 3D scanner (PTS-H400). The marking is completed in 1 minute. The marking points are stuck on the fixture, and the workpiece does not need to be marked again.

2. The workpiece is scanned. Our technical engineers use a camera-type 3D scanner (PTS-H400) to scan, and it takes 2 minutes to obtain 3D data of automobile brake parts.

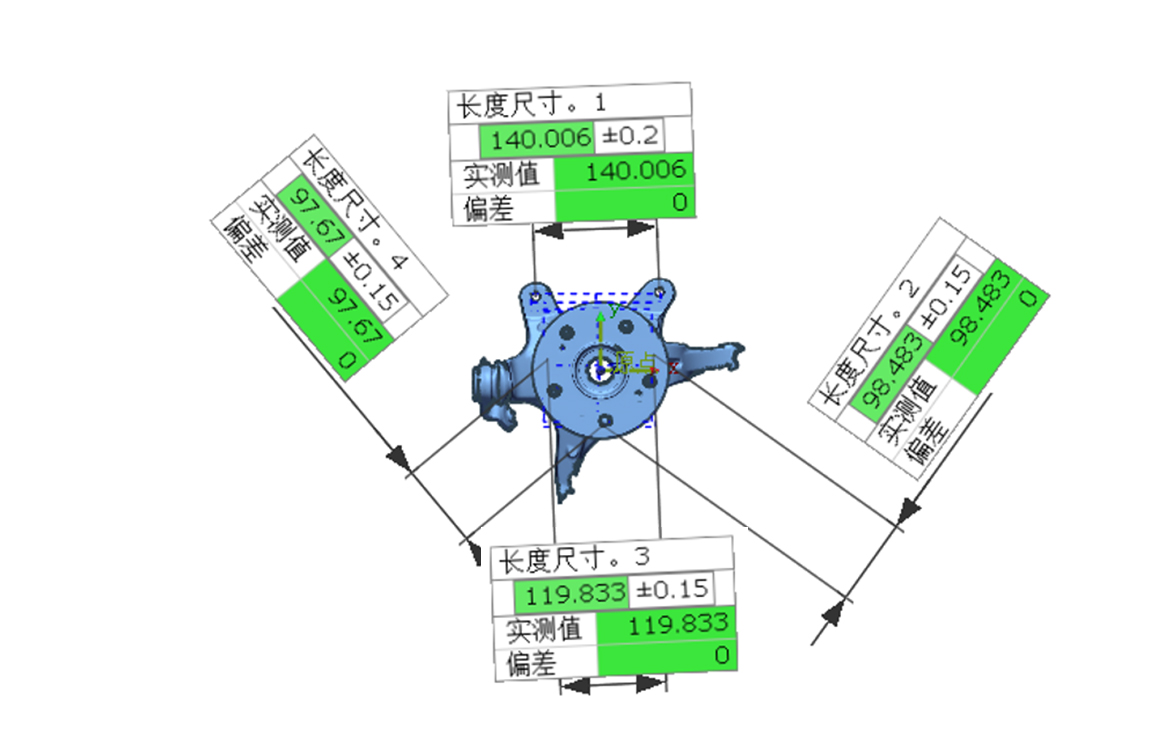

3. Conduct 3D scanning digital-analog comparison of auto parts, measure the dimensions of auto brake parts, curved surface radian and other parameters, and conduct simulated assembly of modified auto brake parts in 3D software.

The value of 3D detection solutions for automotive brake accessories

1. Modification detection

The 3D shape data of the scanned object can be obtained through the photo-type 3D scanning technology, and the obtained 3D scanning data and modified 3D data can be used for 3D simulation assembly analysis, so that the numerical information of each position can be easily obtained, providing a good solution for the modification of large curved surface and complex structure. In addition, data such as coaxiality, hole spacing and assembly clearance can also be easily obtained through the fitting of 3D data, and two-dimensional size can be extracted and obtained from 3D data.

2、Motion state analysis

The photo-type 3D scanner can scan open and closed parts such as car brakes in different states, so as to obtain the structural relations of open and closed parts in different motion states, and provide accurate 3D data for subsequent structural analysis, dimension design and other aspects.

The highlights of a photo-type 3D scanner

1. Not restricted by the environment, non-contact scanning

2. Not limited by the size of the tested workpiece

3. Full-size scanning inspection of workpiece

4. Fast speed and high precision

5. Multi-product testing, diversification (such as product testing, mold testing, etc.)

6. Reverse design and development can be realized

Summary of 3D detection solutions for auto brake Parts:

Jingyixun adopts photo-type 3D scanner to conduct 3D scanning on auto brake parts, quickly obtain complete 3D data of auto brake parts, conduct 3D scanning on auto brake parts at different stages in the modification process, generate accurate 3D data report, and analyze omni-directional deviation of point, line and surface. The efficiency of photo-type 3D scanning is high, which can greatly reduce the test cost and expand the competitive advantage of refitting industry.

Related products

PTS-A series (binocular) photographic white light 3D scanner PTS-A series (four - eye) photographic white light 3D scanner

0755-86131192

0755-86131192

0755-86131192

0755-86131192