In modern production, the use of manual inspection of product quality will not only reduce industrial production efficiency, but also reduce the accuracy of detection, which will cause many undesirable factors in industrial production. However, the use of a handheld laser 3D scanner for industrial inspection can effectively eliminate these problems. Not only is the detection accuracy high, but it can also make up for the 3D shape detection that cannot be detected during manual inspection. Only a handheld laser 3D scanner is needed to assist the computer. It can solve a large labor cost and improve production efficiency.

Hand-held laser 3D scanner for 3D scanning and 3D inspection of large-size castings are as follows:

Customer demand:

1. Test object: large-size casting

2. Customer needs: Quickly obtain the 3D model of castings for quality inspection (3D surface inspection), and find that the quality of castings requires 3D inspection of the production mold, and analyze and judge the problem through 3D surface inspection.

3. Current difficulties that customers need to solve

Casting parts are relatively large and heavy, and cannot be manually inspected. The surface accuracy requirements are high. The traditional three-coordinates are difficult to detect, the inspection efficiency is slow, and the complete data of complex parts are difficult to obtain.

Large-size casting 3D size inspection solution-handheld laser 3D scanner

1. Preparation

Choosing a suitable 3D scanner, the technical engineer chose a handheld blue light 3D scanner (eSharp P10) to scan large-size castings. The marking is completed in 2 minutes, and the larger outline marking points can be directly stuck on the object itself

2. The workpiece is scanned. Our technical engineers use a handheld blue light 3D scanner (eSharp P10) to scan to obtain 3D data of large-size castings.

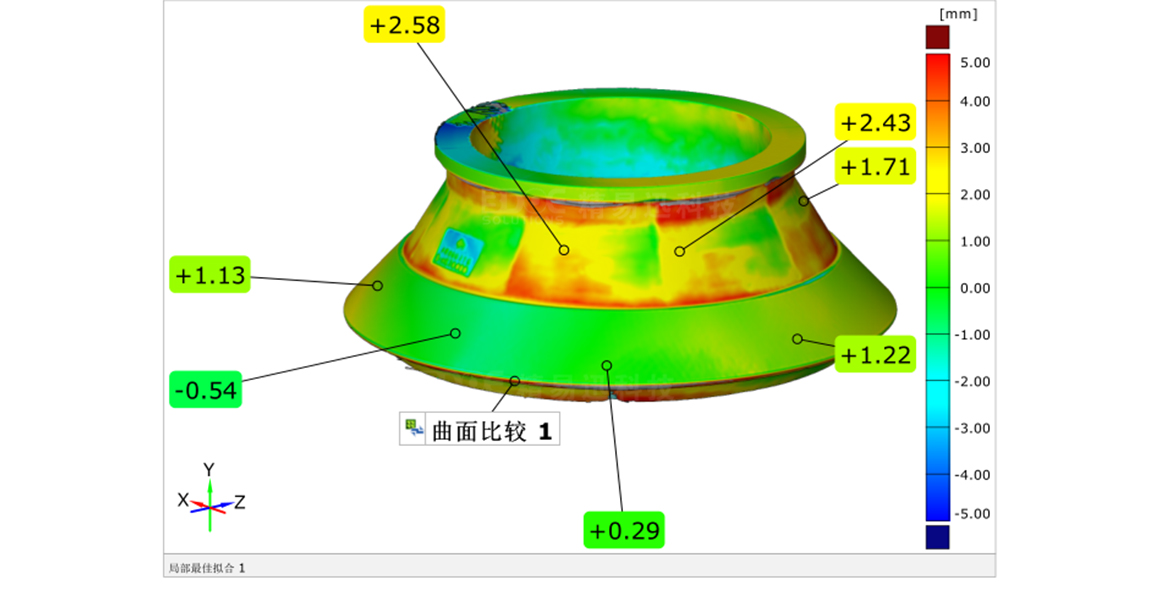

3. Perform 3D inspection and comparison of large-size castings, measure the contour of the casting, the curvature of the curved surface and other parameters, and mark the deviation results

The value of 3D inspection solutions for large-size castings

1. The traditional measurement method generally only measures several key positions to determine whether the tolerance requirements are met. It is difficult to cover all the positions of the workpiece. 3D scanning uses millions or even tens of millions of point data to achieve nearly 100% of the object. Full coverage measurement.

2. The measurement data is objective and accurate

There are no factors that are difficult to control due to human measurement operations, such as the accuracy of measuring tools, the mental state of the operator, accidental errors, and digital electronic archives.

3. It can solve a large number of difficult problems in traditional 3D inspection

Manually difficult to measure problems such as arc or curved surface, form and position tolerance, coaxiality, and roundness of a single hole, 3D scanning can quickly solve

4. Business economic benefits

Workers are getting more and more difficult and the cost is getting more and more expensive. The use of 3D scanning technology can replace (reduce) a certain amount of labor.

Summary of 3D inspection solutions for large-size castings

Jingyixun uses a handheld blue light 3D scanner to perform 3D scanning on large technical castings, quickly obtain complete 3D data of the castings, and perform 3D inspections on large castings at different stages in the production process, which can generate accurate CAV surface inspections Report, analyze the all-round deviation of points, lines and surfaces. The high efficiency of handheld blue 3D detection can greatly reduce the cost of detection and expand the competitive advantage of manufacturing enterprises.

0755-86131192

0755-86131192

0755-86131192

0755-86131192