The 3D scanning reverse design of parts adopts a photographic 3D scanner to quickly obtain 3D scanning data of parts, with an accuracy of 0.02mm. The 3D scan data obtained by scanning can be directly imported into reverse design software, CAD/CAM software, etc. The data can be adjusted and repaired in the CAD system, which can greatly shorten the product design cycle.

The problem we are facing

1. Customers have high requirements for 3D scanning accuracy of parts and components, and need to obtain high-precision 3D scanning data

2. The accuracy of the hole itself and the relative accuracy between the matching structure and the matching structure need to meet very important requirements

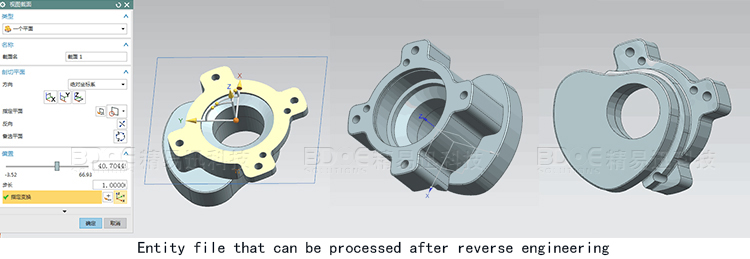

3. Combined with high-precision 3D scanning data, technical engineers use 3D design software to reverse drawing design of parts

Reverse design solutions for parts

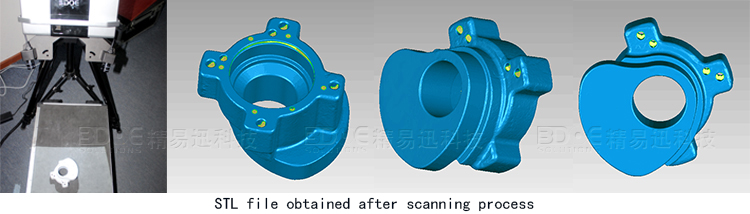

1. Obtain high-precision 3D scan data of parts through a camera-type 3D scanner

The camera-type 3D scanner adopts raster scanning technology, intelligent point cloud stitching, efficient software graphics algorithms, and fast data processing functions. It can easily obtain 3D scanning data of parts. Obtaining 3D data is the first step in reverse design. The quality directly affects the quality of the final reconstructed model surface.

The built-in functions of the Jingyixun 3D scanning software can assist in the simple post-processing of point cloud data (filling holes, removing overlap, removing noise, etc.), helping to complete the reverse design faster. As for the accuracy of the hole itself, the experienced 3D scanning engineer sometimes not only scans the parts individually, but also needs to assemble all the parts and scan them as a whole, so as to obtain the precise assembly position. After the design of a single part, problems such as precise assembly, whether there will be interference during assembly, and whether the assembly position is correct or not can be easily overcome.

2. The reverse design of parts adopts professional surface reconstruction software to make the reverse design more automatic and efficient. Using professional reverse design software to ensure that users get perfect polygons and NURBS models can output industry standard formats, including STL, IGES, STEP and CAD and many other file formats.

Reverse design solutions for components. To collect high-precision and accurate 3D scanning data, the Jingyixun 3D scanner is an indispensable tool. The 3D scanner is used to copy the number of parts to ensure the quality of product design and effectively reduce design and production costs. At the same time, the photographic 3D scanner acquires the processed 3D CAD data, which is convenient for reverse design and inspection, and is conducive to archiving. It can quickly establish a product's 3D database and provide a good data foundation for subsequent product design improvements and inspections.

0755-86131192

0755-86131192

0755-86131192

0755-86131192