Wood carving has an important position in my country's traditional crafts. Ancient buildings and furniture are inseparable from wood carving crafts. Wood carvings are loved and sought after by people for their beautiful shapes and fine carvings. However, with the development of society and the different aesthetics of people, traditional woodcarving craftsmanship has been difficult to integrate into people's lives. Therefore, many woodcarving products are limited to collections and are not closely related to people's lives in ancient times. The popularization of modern mechanization in woodcarving technology has become a trend. Hand-carving is time-consuming and laborious. An ordinary woodcarving work takes days or even months, while machine carving only takes tens of minutes, and even dozens of pieces can be carved at the same time. For works, mechanical engraving needs to be supported by 3D data to complete. In the case of few people engaged in wood carving industry, it can also meet the supply of wood carving art market.

The following is the combination of Jingyixun 3D scanner and CNC engraving machine to quickly and high-fidelity 3D digitization of woodcarver master's carving works, and then direct processing by CNC engraving machine, which can be completed in a few hours at most, especially suitable Reproduction and mass production of antique furniture, European-style furniture accessories, large-scale wood carving crafts.

Customer demand:

1. Can quickly obtain wood carving 3D data to assist in rapid design

2. 3D data can be directly input into the engraving machine software, and finally engraved

3. Can clearly obtain wood carving texture, improve design time and reduce labor

Current difficulties that customers need to solve:

1. The traditional way is to have a designer give drawings (forward design), which is difficult and takes a long time, and the effect of the design will be biased in processing, resulting in waste of materials;

2. The works of woodcarvers can be digitalized with high fidelity (3D data archive)

Woodcarving 3D scanning reverse solution (Blu-ray 3D scanner)

1. Preparation

First, surface treatment of the scanned sample is required: paste the mark points. The three-dimensional scanning system needs to superimpose the common mark points identified between the two scans so that the two scans exist in a unified coordinate system to achieve complete data splicing.

2. The wood carving samples are scanned in 3D. Our technical engineers use the blue light 3D scanner (PTS-E) to scan to quickly obtain the 3D data of the wood carving samples.

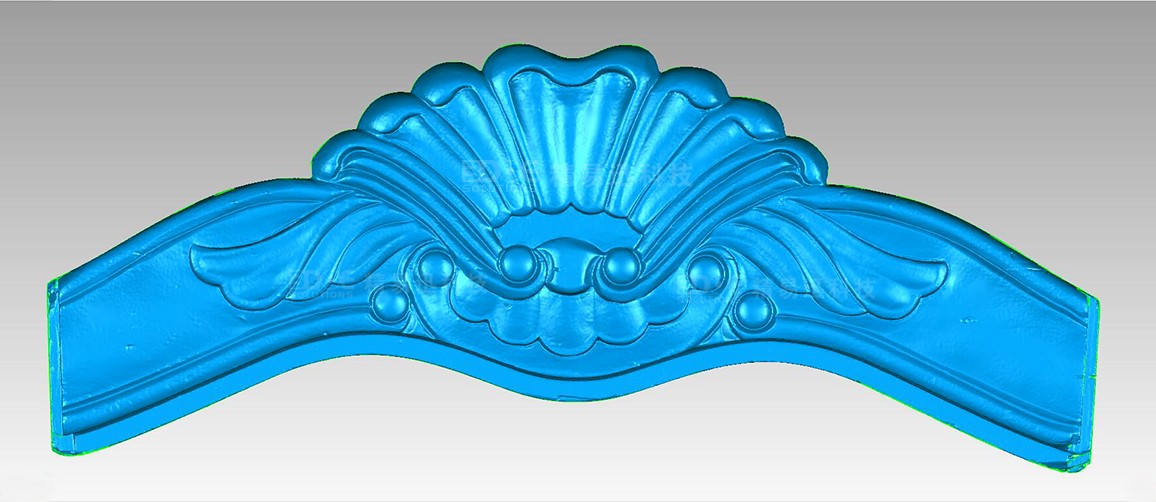

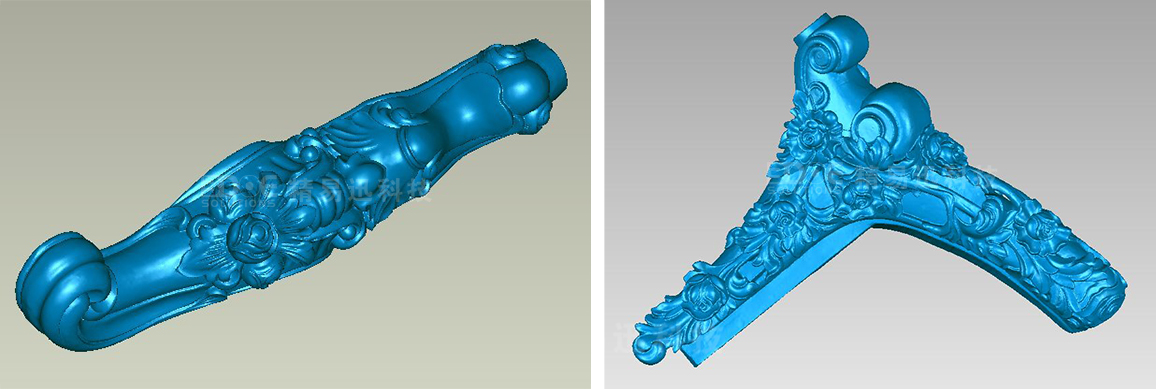

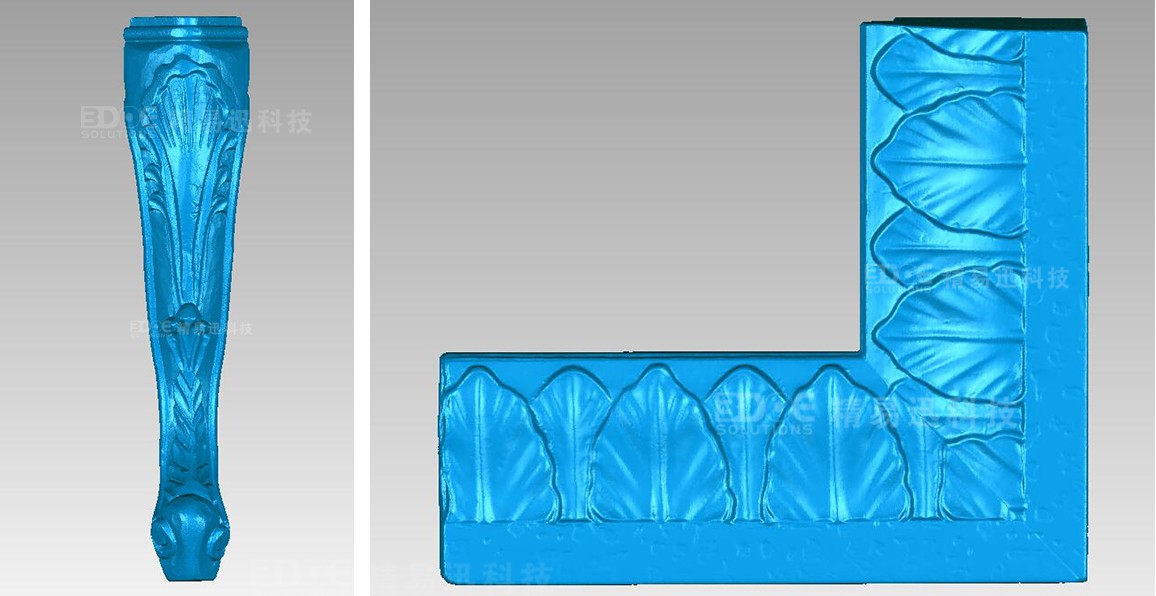

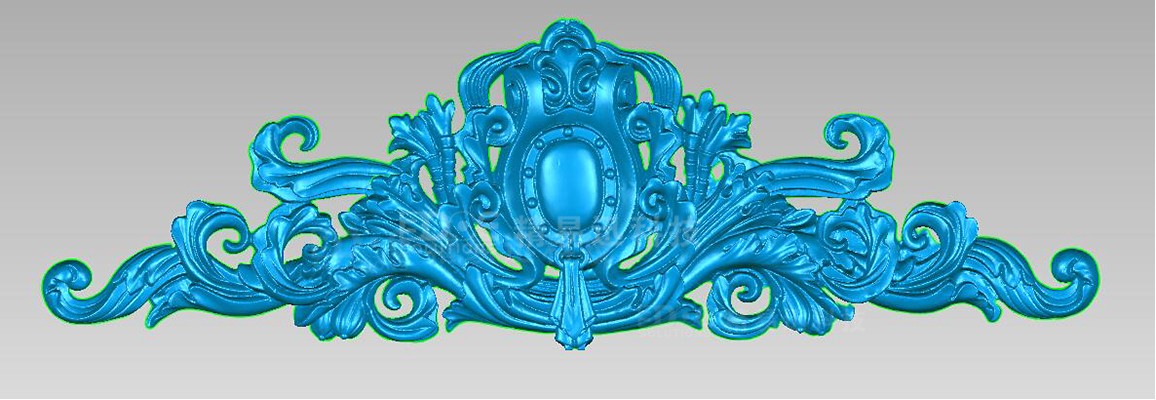

Chinese and European woodcarving furniture scanned by 3D scanner are displayed as follows:

Highlights of the Blu-ray 3D scanner used in the 3D scanning reverse solution of woodcarving samples

1. Using blue light non-contact scanning, will not cause any damage to the surface of the object

2. Multi-angle scanning, automatic stitching, can avoid dead ends as much as possible

3. The scanned data is packaged by geomagic and converted into STL, which can be imported into Jingdiao software

4. Industrial-grade precision, the scanned 3D data can be used to engrave fine textures with an engraving machine to meet the customer's expected requirements.

Summary of 3D scanning reverse solutions for woodcarving parts:

Generally, woodcarving customers require the same effect as the works of woodcarving masters. The photographic 3D scanner can easily meet the needs of customers; for the processing time, it originally takes 1 day or even half a month for drawing time (depending on the complexity of the pattern) , Now it only takes ten minutes to half a day to complete; it can improve the industrialization ability of woodcarving artworks.

0755-86131192

0755-86131192

0755-86131192

0755-86131192