Jingyixun's blue handheld laser 3D scanner is a new generation of scanners for industrial products. Compared with traditional laser scanners and three-coordinate measurement systems, its measurement speed is increased by dozens of times. As the integration error is effectively controlled, the overall measurement accuracy is greatly improved. It uses 14-line laser projection onto the measuring work surface, scans with a high-resolution CCD camera, and uses optical photographic positioning technology to measure the principle, which can obtain a complete point cloud of a complex work surface in a very short time. Its unique mobile design and automatic splicing technology of point clouds from different perspectives make scanning without the help of machine tools, and the scanning range can reach several meters, while scanning large workpieces becomes efficient, easy and easy.

Customer demand:

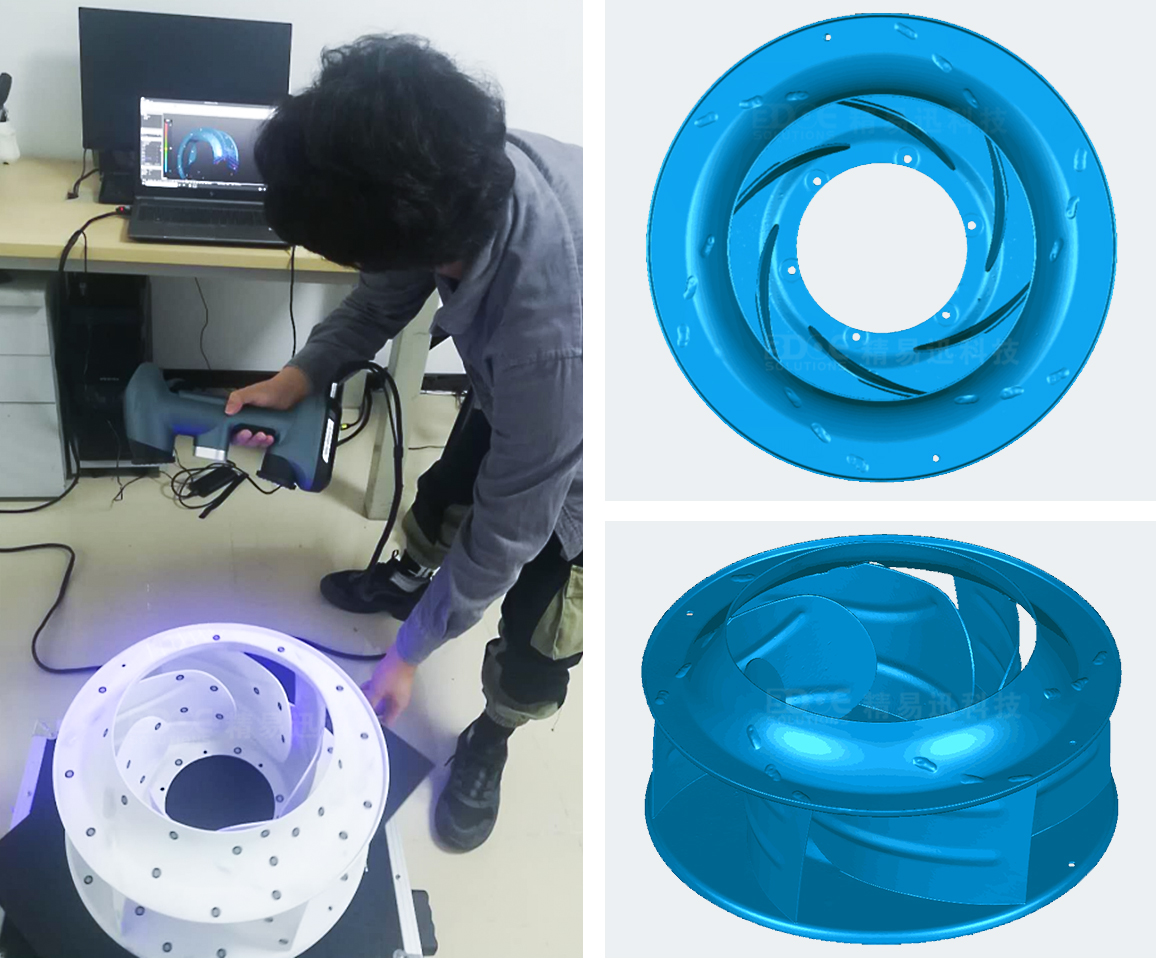

1. Scanning object: fan blade

2. Customer demand: quickly acquire the 3D model of the fan blade and carry out reverse design, which requires high precision and directly provide the 3D solid diagram

3. Current difficulties that customers need to solve: high requirements for precision of fan blade, traditional forward design drawing, slow efficiency, difficult to obtain complete data of complex parts, difficult to ensure the precision of product processing

Fan blade 3D scanning reverse design mold opening solution (blue handheld laser 3D scanner)

1. Preparation

First, surface treatment of the scanned sample:

1) Since the 3D scanner uses optical methods to scan objects, some objects that reflect light, transmit light or absorb light on the surface of the object need to be surface treated and sprayed with developer

2) Paste the marked points, and the splicing of marked points is executed by software algorithm. The three-dimensional scanning system needs to superimpose the common mark points identified between the two images so that the two scans exist in a unified coordinate system, so as to achieve complete data splicing

2. The workpiece is scanned, our technical engineers use a blue handheld laser 3D scanner (eSharp-p) to scan to obtain 3D data of the fan blades

3. 3D reverse design drawing of the fan blades, and import the STL data scanned by the camera-type 3D scanner into the reverse drawing software for drawing

Highlights of the blue handheld laser 3D scanner used in the fan blade 3D scanning reverse program

1. The operation is simple and easy to learn

2. Non-contact blue light 3D scanner

3. Quickly obtain 3D data of fan blades

4. Reversible design, secondary design modification

5. Can quickly obtain 3D size

6. Reduce drawing modification

Summary of 3D scanning reverse design mold opening solutions for fan blades

The blue light handheld laser 3D scanner performs accurate scanning and quickly provides customers with reverse engineering data processing. According to the physical model of the existing part (or called the original part), the process of reconstructing the original CAD model using various digital technology and CAD technology. Jingyixun blue handheld laser 3D scanner can directly obtain high-precision three-dimensional data of parts, and use software to construct curved surfaces or entities to make them the required three-dimensional data model for secondary design and open mold mass production.

0755-86131192

0755-86131192

0755-86131192

0755-86131192