电话:0755-86131192

邮箱:info@3doe.com

地址:深圳市龙华区民治大道民治商会大厦六楼

The PTS-C series adopts an integrated structural design style with high hardware integration and can freely switch between different measurement ranges. It adopts fully autonomous hardware control technology, industrial-grade high-speed 3D scanning, and the single scanning speed can reach 1.5 seconds, which has better precision and better dynamic applicability. Advantages of blue light: The shorter the wavelength, the better the reflectivity, and the better the imaging effect for objects with complex textures!

The PTS-C series 3D scanner adopts an integrated structural design style, high hardware integration, and can freely switch between different measurement ranges. It adopts fully autonomous hardware control technology, industrial-grade high-speed 3D scanning, and the single scanning speed can reach 1.5 seconds, which has better precision and better dynamic applicability.

Features:

1) Non-contact blue light scanning, the light source is fine.

2) Both multi-color light scanning technology and better light sensitivity adaptability.

3) Display of higher details, with an accuracy of 0.015~0.05mm.

4) The camera resolution is 1.3 to 2 million pixel specifications, the higher the resolution, the more details of the scan.

5) Optimized processing technology for large data volume.

Self-developed and manufactured, independent software intellectual property protection software is continuously upgraded for free, professional R & D team, provide 24-hour machine service, can be customized according to customer needs.

Photographic 3D scanner-measurement principle

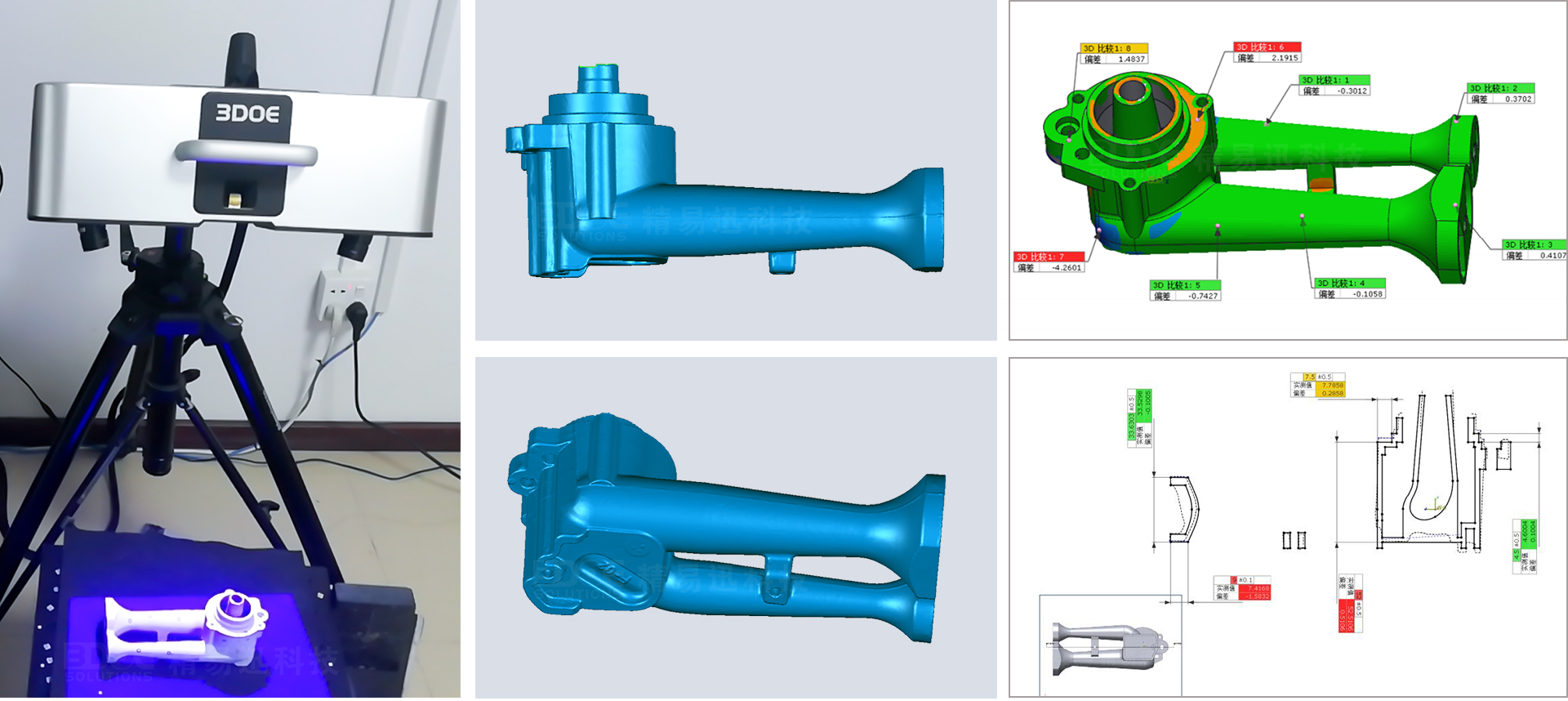

The 3DOE 3D measuring head is composed of two high-resolution industrial CCD cameras on the left and right and a grating projection unit. The structured light measurement method is used to project a group of grating fringes with phase information onto the surface of the measured object using the grating projection unit. The two cameras on the left and right can measure simultaneously, and combine computer vision technology, photoelectric sensor technology, image processing technology and software control technology to obtain high-density three-dimensional data on the surface of the object in a very short time. The rotating object or scanning head is used to change the scanning angle of view. Based on the automatic splicing technology of multi-view point cloud, it can complete 360° scanning of the object in all directions.

Advantages of blue light: The shorter the wavelength, the better the reflectivity, and the better the imaging effect for objects with complex textures!

▣ Classic cases

Gas stove 3D scanning inspection

▣ Technical Parameters

Number of lenses | Binocular type | |

Product number | PTS-C130 | PTS-C130-So |

scanning method | Non-contact blue light scanning | |

Single scan range (mm2) | 100X75~400 X300 | 50X40~200 X150 |

Maximum measuring range (mm3) | 2000×1500×1500 | 1000 X750 X750 |

Measuring accuracy (mm) | 0.02~0.05 | 0.015~0.03 |

Single scan points (pixels) | 1,300,000×2 | |

Single scan speed(S) | <2 | |

Average dot pitch (mm) | 0.07 ~ 0.3 | 0.04 ~ 0.15 |

Output file format | ASC, STL, OBJ, etc., can be connected with Geomagic, Imageware, 3Dmax, etc. | |

Splicing method | Automatic splicing of marked points, intelligent fusion into a single layer point cloud | |

Number of lenses | Binocular type | |

Product number | PTS-C200 | PTS-C200-So |

scanning method | Non-contact blue light scanning | |

Single scan range (mm2) | 100X75~400 X300 | 50X40~200 X150 |

Maximum measuring range (mm3) | 2000×1500×1500 | 1000 X750 X750 |

Measuring accuracy (mm) | 0.02~0.05 | 0.015~0.03 |

Single scan points (pixels) | 2,073,600 X 2 | |

Single scan speed(S) | <2 | |

Average dot pitch (mm) | 0.05 ~ 0.21 | 0.03 ~ 0.1 |

Output file format | ASC, STL, OBJ, etc., can be connected with Geomagic, Imageware, 3Dmax, etc. | |

Splicing method | Automatic splicing of marked points, intelligent fusion into a single layer point cloud | |

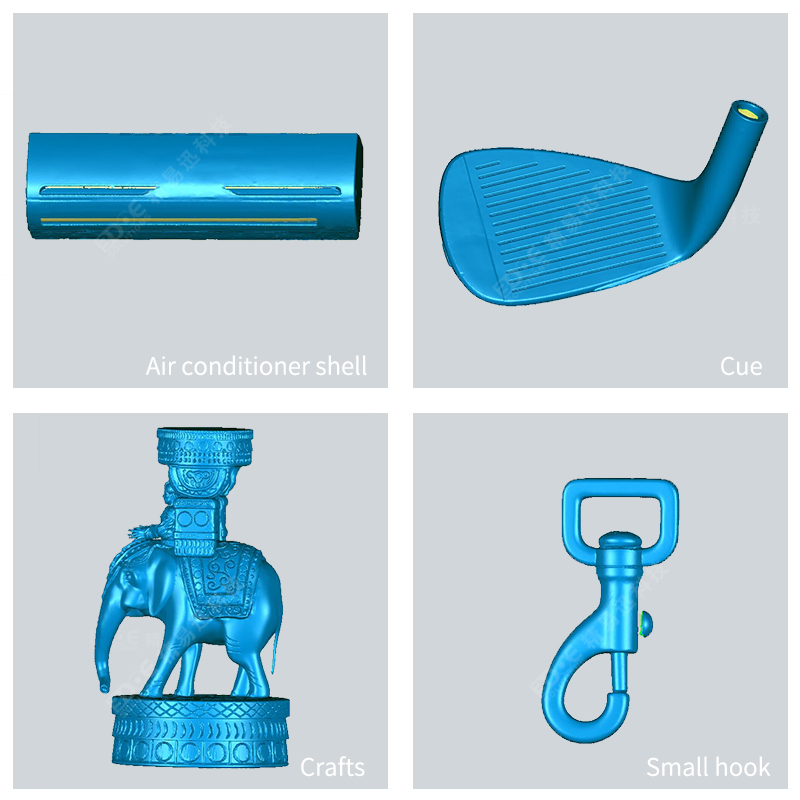

▣ Application field

●Auto Parts

●Industrial Design

●Reverse design (copy number)

●Mold design and inspection

●Handicraft Scan

●Wood carving scan

●Clothing Design

●Game production

●Household appliances

●Electronic Products

●Teaching Research

●Cultural relics and archaeology

To understand the specific application, please feel free to consult online (message) or

call 0755-86131192!

Provide system customized solutions!